Inspection and Special Processes

Finishing, Testing & Inspections

Pursuit Aerospace in-house inspection, testing, and special processes help maintain cost efficiencies and delivery timeliness. Our highly-skilled experts and our carefully designed special processes help ensure the parts you receive will perform to design intent.

CMM

A coordinate measuring machine (CMM) tests final products against design intent by measuring precise physical geometrical characteristics of an object using a probe and laser scanning technology.

Blue Etch Anodizing

Blue etch anodizing (BEA) is specialized, highly sensitive non-destructive testing (NDT) technique for detecting surface discontinuities such as laps, cracks, material segregation, heat-treating imperfections, and abnormalities by machining.

FPI

Fluorescent Penetrant Inspection (FPI) is a type of dye penetrant inspection in which a fluorescent dye is applied to the surface of a non-porous material in order to detect defects that may compromise the integrity or quality of the part in question.

Heat Treating

Heat Treating is used to provide final and/or intermediate material properties and stress conditions necessary for end use or intermediate processing. Heat treating is an additional way to help enhance material properties in our forgings to product reliable end-use hardware. This process is carried out in tightly controlled furnaces.

Chemical Processing

Chemical Processing is used to clean, prepare, and inspect forgings during the forging manufacturing process. Chemical processing allows for mass production of operations that would otherwise be tedious and labor intensive when other methods are used. Chemical processing is carried out by various methods, including manual and automated operations though multiple compositions of chemical baths.

- Chemical Processing

- Acid Cleaning

- Alpha Case Removal

- Blue Etch Anodize

- Chemical Milling

- Dry Film Lubricant Coatings

- Etching & Etch Inspection

- Macrostructure Etch

- Pre-Penetrant Etch

- Solution Analysis & Testing

- Titanium Cleaning – Acid

- Holemaking

- Milling

- Turning

- With Hardness Testing

- Nital Etch

- Material Testing

- Mass Airflow Measurement

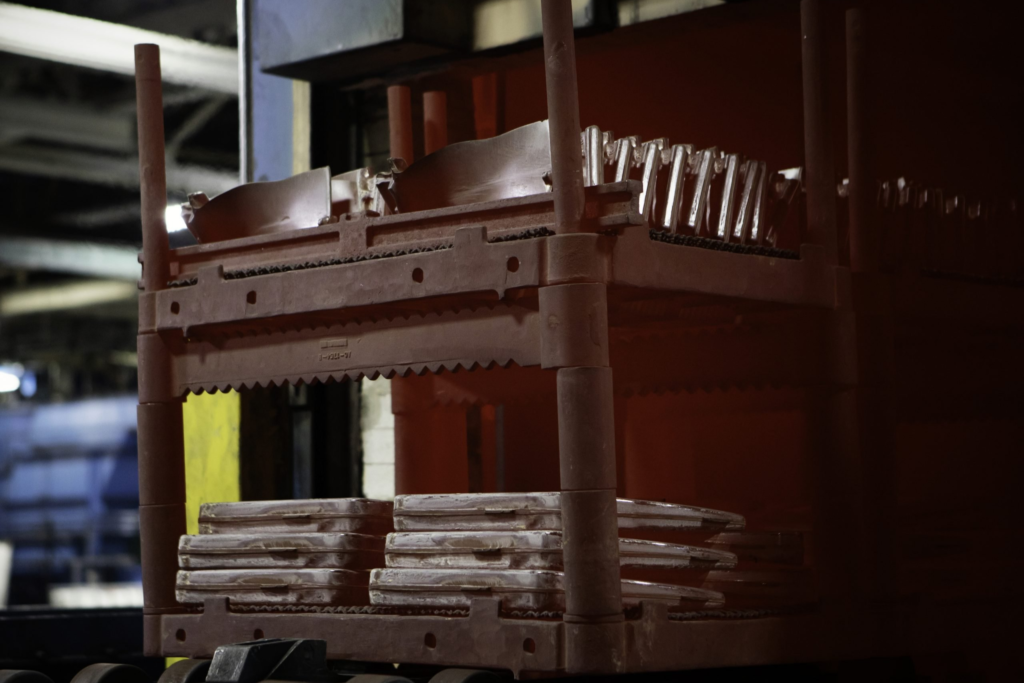

- Screw Press

- Mechanical Press

- Hydraulic Press

- Electrical Discharge Machining (EDM)

- Wire

- Sinker

- Small Hole

- Cutting

- Drilling

- Fluorescent Penetrant Inspection (FPI)

- Type 1 Method A Sensitivity Level 3

- Type 1 Method D Sensitivity Levels 3 & 4

- Film Radiography Survey (Xray)

- Magnetic Particle Testing (MPI)

- Fluorescent We Horizontal Method

- Visual Testing (VT)

- Glass, Steel, Shot & Ultra Sonic Peening

- Welding

- B (Torch/Induction)